Thursday, April 1, 2010

Wednesday, March 10, 2010

Tuesday, March 9, 2010

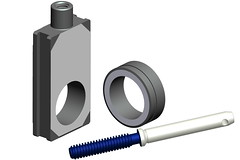

REVERSE ENGINEERING

Petrotrim Engineering Services

Petrotrim is your complete source for the design, fabrication and supply of a wide range of equipment, such as:

Consulting, Detailed Engineering drawings and Reverse Engineering.

A calculation and Design Approval service which allows you to specify verification by your choice of certifying body, e.g. DNV, ABS, Lloyds or Bureau Veritas.

Otherwise calculation packages can be prepared to your requirements for internal review.

Design API equipment, Flanges, Hubs, Unions, etc.

Skid Fabrication, will include representations of all major equipment located in the proposed arrangement and will be used as the basis for the actual skid fabrication.

Will prepare and estimate for the process skid fabrication. The estimate will include all engineering, fabrication labor, materials for skid construction.

Convert AutoCAD Drawings to 3D models.

Tuesday, February 23, 2010

Friday, February 19, 2010

Friday, February 12, 2010

ASME/ANSI and API Flanges

The difference between ASME/ANSI and API flanges is the fabrication material and the higher rated API operating pressure.

ASME/ANSI flanges are common in industrial process systems handling water, steam, air and gas. API flanges are manufactured for high strength operating refinery systems with products such as oil and explosive gases.The flange standards API 6A and ASME/ANSI B16.5 are similar dimensionally - but the API 6A flanges are rated for higher pressures.

ASME/ANSI flanges are common in industrial process systems handling water, steam, air and gas. API flanges are manufactured for high strength operating refinery systems with products such as oil and explosive gases.The flange standards API 6A and ASME/ANSI B16.5 are similar dimensionally - but the API 6A flanges are rated for higher pressures.

Tuesday, January 26, 2010

Material Class API-6A

AA-General Service

Carbon or low alloy steel

BB-General Service

Carbon or low alloy steel

CC-General Service

Stainless steel

DD-Sour Service a

Carbon or low alloy steel b

EE-Sour Service a

Carbon or low alloy steel b

FF-Sour Service a

Stainless steel b

HH-Sour Service a

CRA bcd

a) As defined by NACE Standard

MR0175 / ISO 15156.

b) In compliance with NACE Standard

MR0175 / ISO 15156.

c) CRA required on retained fluid wetted surfaces only; CRA cladding of low allow or stainless steel permitted.

d) CRA as defined in API 6A latest edition. NACE MR0175 / ISO 15156 definition of CRA does not apply.

For more information, please see www.petrotrim.com

Carbon or low alloy steel

BB-General Service

Carbon or low alloy steel

CC-General Service

Stainless steel

DD-Sour Service a

Carbon or low alloy steel b

EE-Sour Service a

Carbon or low alloy steel b

FF-Sour Service a

Stainless steel b

HH-Sour Service a

CRA bcd

a) As defined by NACE Standard

MR0175 / ISO 15156.

b) In compliance with NACE Standard

MR0175 / ISO 15156.

c) CRA required on retained fluid wetted surfaces only; CRA cladding of low allow or stainless steel permitted.

d) CRA as defined in API 6A latest edition. NACE MR0175 / ISO 15156 definition of CRA does not apply.

For more information, please see www.petrotrim.com

Wednesday, January 20, 2010

Petrotrim Services, API-6A Temperature Range, Ref. Only

Temperature Operating Range, Classification Degrees Fahrenheit °F

Minimum Temperature is the lowest temperature that the equipment may experience.

Maximum Temperature is the highest temperature that the equipment may experience.

Min. Max.

K -75 to 180

L -50 to 180

N -50 to 140 (Added to API-6A 19th Ed.)

P -20 to 180

R Room Temperature

S 0 to 140

T 0 to 180

U 0 to 250

V 35 to 250

X 0 to 350 **

Y 0 to 650 **

** May Require Derating.

See our website for more information, www.petrotrim.com

Minimum Temperature is the lowest temperature that the equipment may experience.

Maximum Temperature is the highest temperature that the equipment may experience.

Min. Max.

K -75 to 180

L -50 to 180

N -50 to 140 (Added to API-6A 19th Ed.)

P -20 to 180

R Room Temperature

S 0 to 140

T 0 to 180

U 0 to 250

V 35 to 250

X 0 to 350 **

Y 0 to 650 **

** May Require Derating.

See our website for more information, www.petrotrim.com

Friday, January 15, 2010

Petrotrim Services provides the "NEW" style Body Bushing. Some other companies provide the "OLD" style Body Bushing. Below is the difference between the two different styles, NEW vs. OLD.

The new Body Bushing is designed to overcome the following problems.

1) Eliminate pressure trapping in the valve cavity when the gate is either fully open or closed.

2) Eliminate the tendency for the Seat Ring and Body Bushing to seal on the pressure side of the gate. (Upstream sealing). This effect increases the force to move the gate.

In most cases the Teflon Seal Ring is the same one used on the Stellite Seat Ring.

Please see our website for more information.

The new Body Bushing is designed to overcome the following problems.

1) Eliminate pressure trapping in the valve cavity when the gate is either fully open or closed.

2) Eliminate the tendency for the Seat Ring and Body Bushing to seal on the pressure side of the gate. (Upstream sealing). This effect increases the force to move the gate.

In most cases the Teflon Seal Ring is the same one used on the Stellite Seat Ring.

Please see our website for more information.

Subscribe to:

Posts (Atom)